Singapore and Spain, 26th November 2024 – Quantified Energy Labs Pte. Ltd. (QE-Labs), an innovator in photovoltaic (PV) automation solutions, and Ingeteam, a global leader in power electronics and energy conversion industry, have successfully tested an innovative approach to pave the way for using drone coupled Electroluminescence (EL) inspection as routine in-situ QA/QC testing for solar power plant lifecycle asset management. By combining Ingeteam’s INGECON SUN B Series® Inverter with QE-Labs’ patented autonomous drone EL mapping solution, a joint pilot test was conducted at a groundmounted 2P tracker PV system near Zaragoza, Spain. The test achieved an impressive throughput of 40,000 PV modules in an 8-hour night shift, all without requiring a ground team for current injection steps. This result is a remarkable 400% increase over QE-Labs’ previous state-of-the-art throughput of 10,000 modules per night, which relied on energizing one PV string in sequence with an external DC power supply device. This record-breaking performance sets a new benchmark in large-scale PV inspections.

View demonstration video footage of the inspection system in action here:

During the pilot test, it starts from an operator turn on string current injection function at the Ingeteam inverter control system enabling remote current injections into PV strings across string combiner boxes, facilitating rapid and uninterrupted inspections without the need for manual string connections or disconnections. The next step is adopting QE-Labs’ fully integrated autonomous drone EL mapping solution, which incorporates customized hardware, advanced software, and automated flight capabilities. The EL drone is able to scan an entire inverter’s worth of modules (approximately 2,500) at speeds of up to 5.5 m/s in a continuous flight lasting only 20 minutes, with no need for battery replacement. This streamlined process delivers an average throughput of 5,000 modules per hour with a single drone and its certified pilot.

The Ingeteam inverter is capable of supplying current to individual strings at up to the module’s Isc. However, to optimize energy use, the EL inspection is conducted at a current level of 60% of Isc, keeping energy consumption efficient. Approximately 5,000 kWh are required per night to achieve a full 40,000-module throughput.

This innovative approach minimizes labor-intensive procedures of EL inspection, making it practical and cost-effective for large-scale solar asset owners focused on maximizing operational efficiency.

«Ingeteam’s inverter technology has proven to be a powerful tool for enabling full-site PV module inspections with unprecedented efficiency,» added Juan Carlos Jadraque, Deputy Managing Director of Solar PV & BESS at Ingeteam. «All of our central utility inverters support the current injection required for EL inspections. These include INGECON SUN 3Power C Series, INGECON SUN 3Power U C Series 5+, and INGECON SUN Power B Series. Working with QE-Labs on this initiative showcases Ingeteam’s efforts to build O&M friendly solar PV inverter products for our clients worldwide.»

«We are thrilled to collaborate with Ingeteam in developing a truly scalable solution for outdoor EL imaging» said Dr. Yan Wang, CEO & Co-Founder of QE-Labs. «This novel approach not only enhances our operational capabilities but also provides solar asset owners with a high-throughput, cost-effective solution that meets stringent quality standards. By making EL inspections fully contactless-similar to emerging techniques such as daylight Photoluminescence (PL) that are still in lower TRL—our market ready solution achieves significantly higher throughput in capturing EL images at the level of details be able to detect module defects such as microcrack, finger disconnection, shunted cell, cold soldering, etc. Additionally, performing inspections at night enables us to avoid disruptions to daytime energy generation.

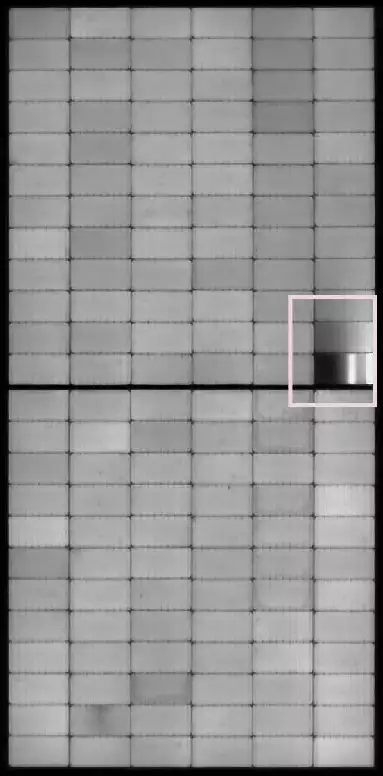

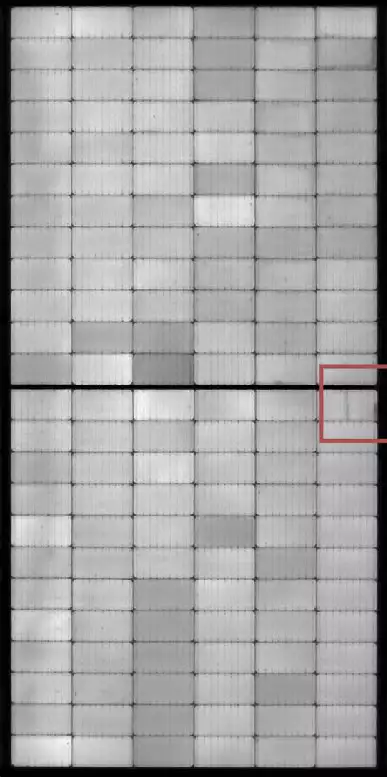

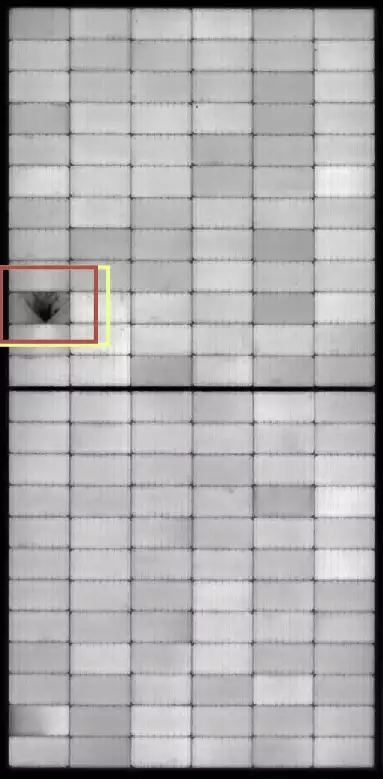

Example of EL images captured from this inspection

Mr. Javier Barricarte Rivas from Salix Solar expressed his enthusiasm as the asset owner operating under a Build-Operate-Transfer (BOT) model: «Drone-based EL inspections allow us to assess the quality of an entire solar farm in a single night—a feat that was impossible in the past. The ability to verify the high quality of our installations so efficiently means we can unlock the potential to draw a higher amount of financial support to build more projects. We are confidently to adopt this solution for our future solar BOT projects.»

About Ingeteam

Ingeteam is a team of 3,500 people in 15 countries, with more than 80 years of experience providing solutions to electrify society in an innovative and sustainable way, through cutting-edge technology specialized in the conversion of electrical energy.

Ingeteam’s rotating electric machines, power electronics, and control and automation electronics technology are applied to the wind, photovoltaic, hydroelectric, battery energy storage, smart grids, railway traction, electric mobility, marine, steel, mining and green hydrogen sectors.

In this way, Ingeteam positions itself as a reference throughout the life cycle of electricity: generation, storage, transmission, distribution and efficient consumption.

About Quantified Energy Labs (QE-Labs)

Quantified Energy Labs, based in Singapore, is a pioneer in photovoltaic inspection, automation, and Al solutions, delivering cutting-edge technology for comprehensive PV asset management. Leveraging drone automation technology and data analytics, QELabs provides end-to-end inspection services that optimize the performance and maintenance of solar assets worldwide. The company focuses on delivering actionable insights through advanced imaging techniques such as Electroluminescence (EL), helping solar asset managers achieve efficient, data-driven plant operations.

For more information, please contact:

- Quantified Energy Labs

Dr. Yan WANG, CEO & Co-Founder

Email: yan.wang@qe-labs.com - Ingeteam

Pablo Rocamora Labat, SA Engineer

Email: pablo.rocamora@ingeteam.com